Origin® One features several integrated cameras for computer vision and capturing temperature data in the IR range; additional sensors measure other environmental conditions during the print process.

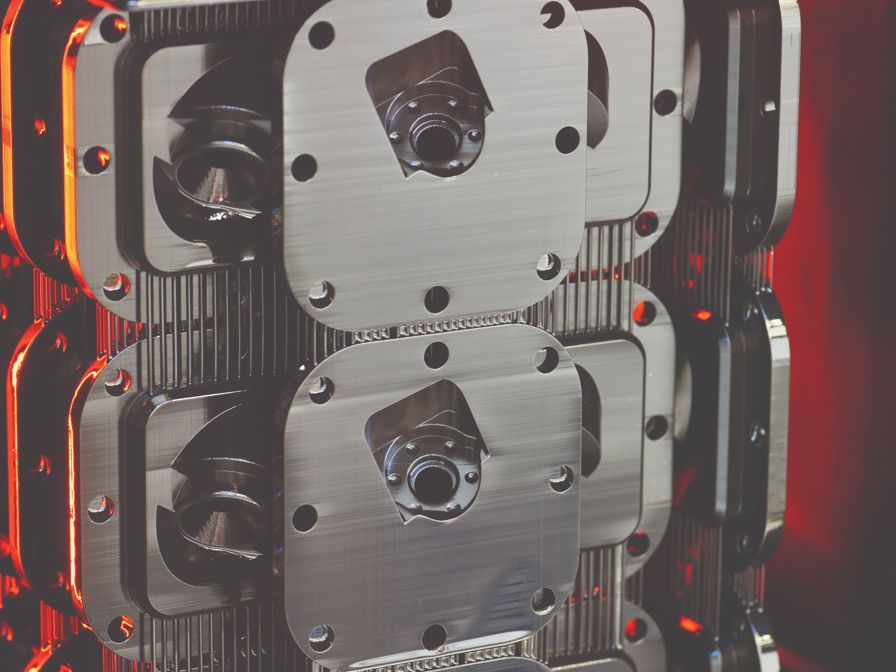

Senior mechanical design engineer Matt Miyamoto designed camera mounts for CNC machining out of black ABS plastic. A compound angle meant that the part could only be machined by a 5-axis CNC (or on a 3-axis CNC with multiple setups), which made the parts expensive to machine at low or high volumes. Matt turned to Origin’s own solution to achieve the quality and throughput required.

Origin One’s Programmable Photopolymerization (P3™) technology precisely orchestrates light, temperature, and other conditions, automatically optimizing prints in real time for the best possible results.

High green strength isotropic prints require minimal support structures and can be stacked throughout the entire build volume, allowing for maximum throughput, minimal waste, and post-processing in minutes. No surface finishing (e.g., bead blasting, polishing, or painting) is required. Origin’s technology is built for additive mass production and produces parts that are functionally and aesthetically suitable for end use.

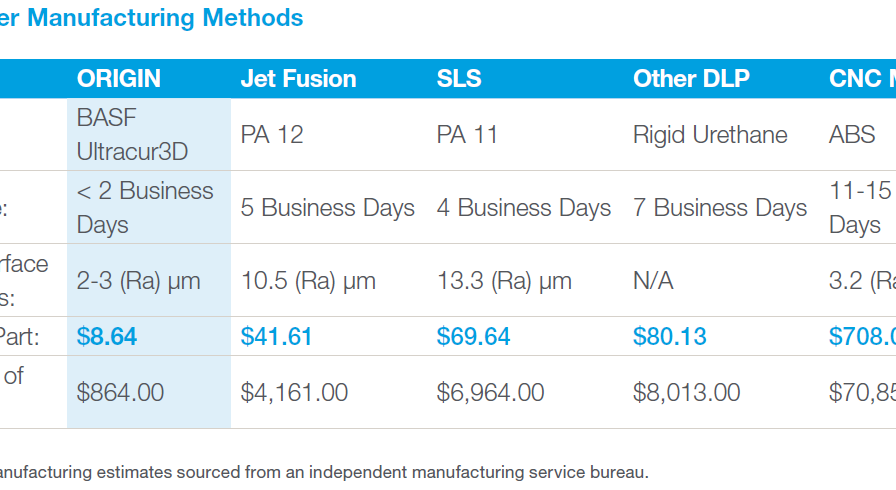

Origin’s Open Material Network includes one of the largest chemical producers in the world, BASF. Origin’s programmable print process is capable of printing a wide range of materials, including BASF’s Ultracur3D, which has a combination of excellent surface finish, mechanical strength, UV stability, and throughput that is unmatched in the industry.

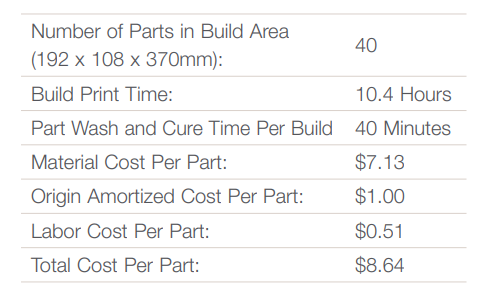

By intelligently packing the parts into the build volume, Origin lab technician Elton Cheung was able to print 40 camera housings in a single print, taking less than 11 hours. Printing overnight enabled maximum printer utilization, and repeating the same print the following morning meant the order was completed in under 24 hours. Post-print, a simple solvent wash, followed by a one minute UV post-cure, rendered the parts ready for use.

Origin One enabled the production of a camera housing for a fraction of the time and cost of CNC Milling or other additive manufacturing platforms. Origin’s throughput and open material network dramatically increase the number of applications for which additive is suitable. Get in touch to discover which of your parts are suitable for open additive manufacturing at scale.