Challenge

The manual support removal process is extremely time consuming and labor intense and inevitably parts damage will impact production yield. Parts design may also introduce support cavities that are hard or impossible to clean using the waterjet system.

Solution

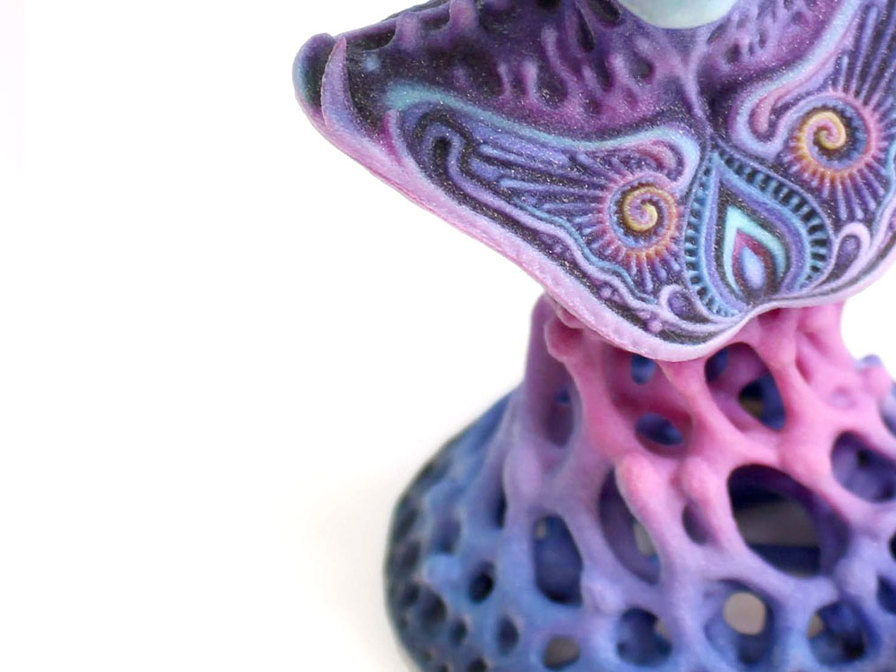

Using WSS™150 water soluble support material allowed for easy, hands-free removal of support material in a single step, without the risk of damage by multiple figurines in a standard dishwasher. Small & medium series productions that require 20-100 parts in one tray and can reach 100s or 1000s of parts in a series can be placed on the same tray inside a dishwasher for fast hands-free support removal. L2S™ was also used to solidify the wastewater, in line with local regulations, for safe disposal without the need to send for onward treatment.

Impact

An automated process for series production was created with a simple workflow. Printed parts were placed in a standard dishwasher minimizing production time and labor requirements. No special skills are required during the hands-free support removal process with water soluble support.