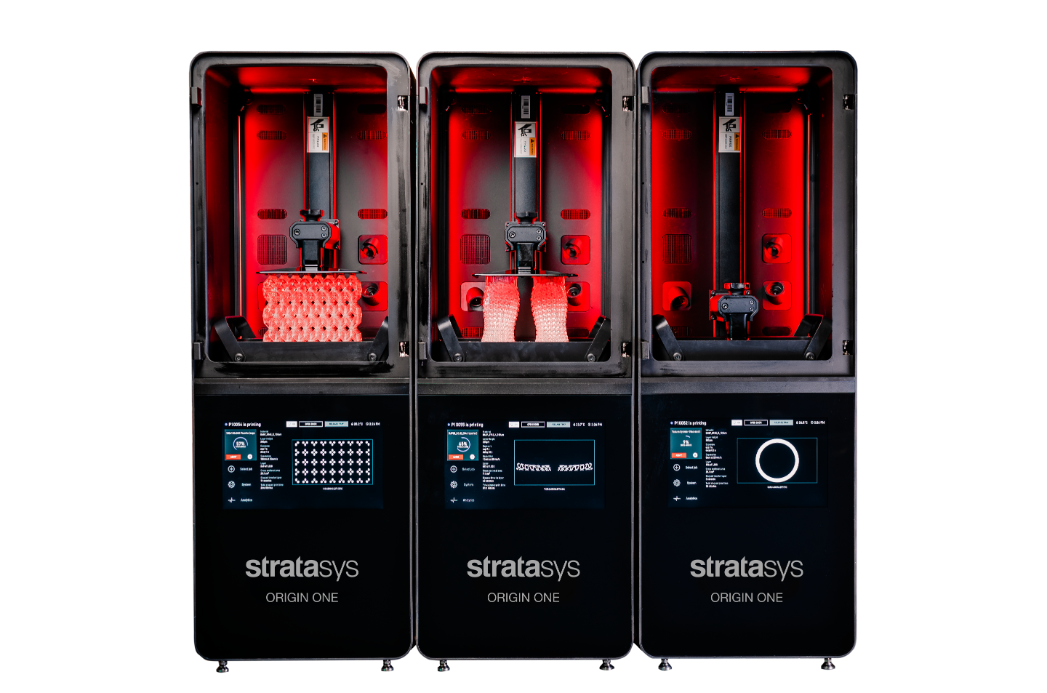

A fully automated additive manufacturing demonstration is making its debut at Formnext 2022. Stratasys has developed the P3™ Automated Production Cell prototype to demonstrate how Stratasys P3 (Programmable Photopolymerization) technology can be scaled to a factory-level solution.

As additive manufacturing production volumes increase, manual involvement in post-processing also grows which can have a negative impact on a manufacturer’s part quality and repeatability. This can significantly disrupt lead times and increase overall production costs. Reducing human error and saving costs while scaling up production is possible, with the P3 Automated Production Cell.

The P3 Automated Production Cell enables 24/7 production with nearly zero operator involvement required. The process is tightly controlled, and the part results are entirely repeatable. Here’s how it works:

This automated process ensures continuous production from printing to final part, streamlining costs and post-production while maximizing throughput. The P3 Automated Production Cell can also be configured with any number of printers and various post-processing equipment to suit various production floor volumes and needs.

The P3 automated production cell prototype is just the first step. Stratasys will continue to push forward on developing a market-ready solution building off the experiences and insight gained at Formnext. Expanding support for other 3D printers beyond the Origin One is also among those plans.

To learn more about the Stratasys Origin One or the P3 automated production cell, contact a Stratasys representative or visit us at Stand D121 in Hall 12.1 at Formnext 2022.