What started for RICOH, a global leader in advanced manufacturing, as an engineering partnership with Stratasys in the early 2000s (to develop PolyJet technology using RICOH printer heads) has blossomed into RICOH 3D for Healthcare—an integrated HIPAA-enabled workflow to develop, design, and produce patient-specific 3D printed anatomic models—powered by Stratasys technology.

3D printed, patient-specific models are increasingly being used for pre-surgical planning to give providers a tactile, visual way to prepare for a case. But at many healthcare facilities, providers and administrators have not been exposed to the latest advancements in patient-specific medical modeling or do not yet have the technical expertise or resources to set up their own 3D printing lab onsite.

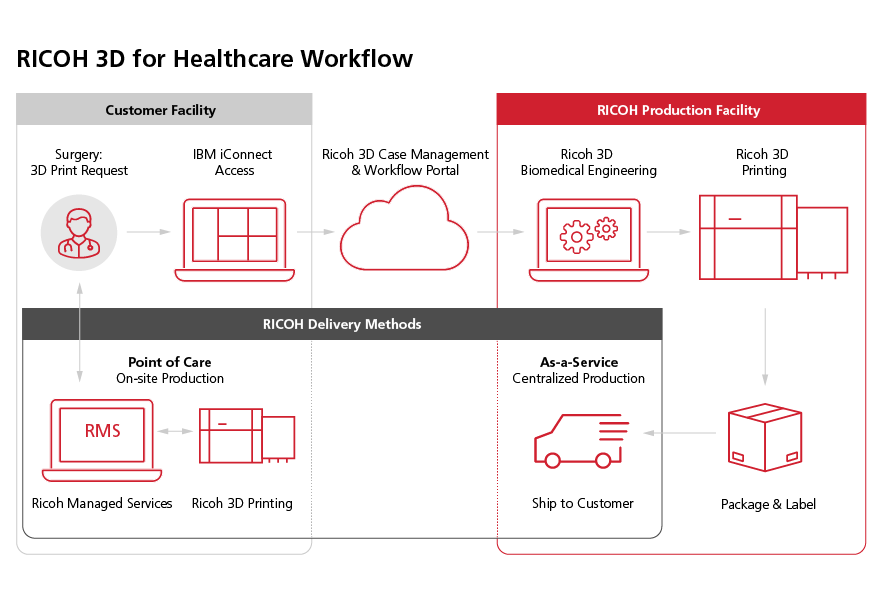

Today, RICOH is leveraging its expertise in advanced manufacturing and logistics to get 3D medical models into the hands of providers in two ways—by offering point-of-care printing where a Ricoh Managed Services team works onsite and manages an entire 3D print lab with Stratasys technology, or an on-demand option where models can be ordered, printed at the Ricoh facility using Stratasys printers, and shipped directly to the provider.

RICOH’s Stratasys technology portfolio includes the following models; J750 Digital Anatomy Printer, F370 FDM printer, J5 MediJet and Origin One.

By harnessing Stratasys technology, the RICOH sales team has been able to more broadly demonstrate the value of patient-specific models and on-premises 3D printing solutions to providers.

Most recently, RICOH 3D for Healthcare received 510(k) clearance from the FDA for craniomaxillofacial and orthopedic patient-specific modeling and ISO 13485 certification for their Quality Management System — important steps to deliver functional, ultra-realistic models to providers across the country.

RICOH’s 3D printing production facility features leading-edge Stratasys technology.

| J750 Digital Anatomy Printer | J5 MediJet | Origin One | FDM 370 |

| For unparalleled visual models including full color and transparency and for simulation of biomechanically accurate functional models ranging from flexible blood vessels to rigid bones. | For high quality, visual and full color models—designed to provide high fidelity color and transparency. | For high speed printing of single material, high resolution models. | For quick, durable, lower cost models made in single material. |