Leverage the advantages of faster EOAT ideation and creation with 3D printing, avoiding the lead time to machine or outsource them. Print your end-of-arm tool overnight and have it working for you the following day.

Make lighter end-of-arm tools that require less power to operate. FDM technology uses strong but lightweight materials ranging from engineering-grade ABS to high-strength thermoplastics. In terms of polymer powder, SAF technology utilizes High Yield PA11 to produce EOAT parts that are accurate and robust mechanical capabilities.

Print EOATs on-demand, avoiding the material and lead time costs of traditional manufacturing. Customization and design changes are as easy as updating the CAD model and printing another tool.

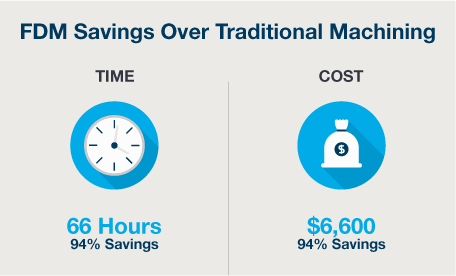

Case: Robai Corporation experienced the above results.